Chrome Casting Balls For Cement

- HY

- China

- 20-45 days

- 50000T

High Chrome Grinding Media balls

Haoyang Hi Chrome Grinding media balls can provide: Cr 1%-28%, hardness: HRC40-66, Dia.10mm-150mm alloy cast steel balls. The balls have a lot of excellent properties, such as higher hardness, good abrasive resistance, together with a good surface finish and small dimensional allowance after scientific heating treatment, as one type of chrome grinding media, it can be widely used in ball mill grinding systems of mines, cement, building materials and chemical industries,etc.

High Chrome Casting grinding balls , chrome concentration is 》10%-14%, Hardness 》HRC 58, High Chrome casting grinding balls is one of the wearable steel balls with better performance -price-ratio, and its extensive usage has won itself a high share in the market .

Envoi ponctuel.

Inspection avant expédition

Une logique complète,

Usines certifiées ISO

Haoyang a des agents partout dans le monde et fournit des solutions de broyage pour l'extraction de l'or. Toutes les marchandises seront inspectées avant leur chargement à bord. Si les rapports de test ne sont pas qualifiés, tous les conteneurs seront retournés aux frais de l'usine! Nous acceptons toutes les réclamations causées par des problèmes d’acier.

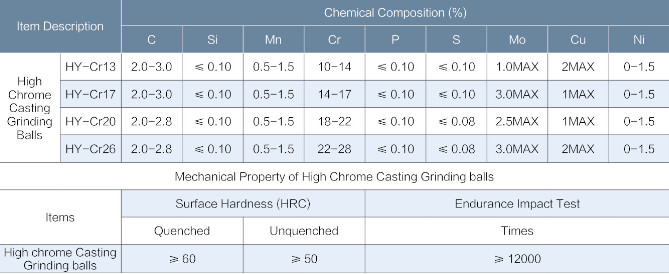

Chrome Casting Balls Classification

Application industry of Grinding steel balls

The size of forged grinding media balls from 20mm to 150mm are widely used in all kinds of mills in the mining industry ( Copper Mining , Gold mining and iron mine )![]()

The Features of Grinding balls :

Steel : Low Carbon Steel , High Carbon and manganese Alloy steel , High Manganese Alloy Steel .

Consistant Surface hardness to Core Hardness ( 58-65HRC)

Grinding balls reach to the high Impact toughness more than 15J /cm2

The lowest broken rate : 125mm Grinding balls have reached to "0" broken rate ,all less than 0.5%

Improved wearing rates

1. High Chrome Casting Balls

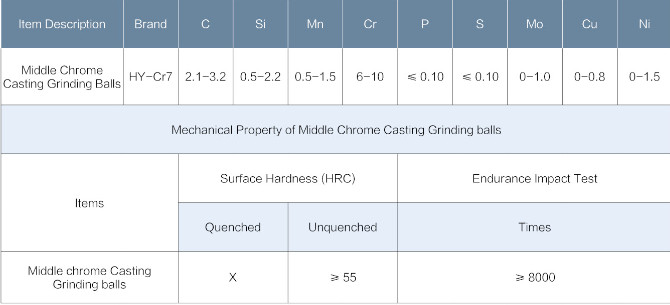

2. Middle Chrome Grinding Balls

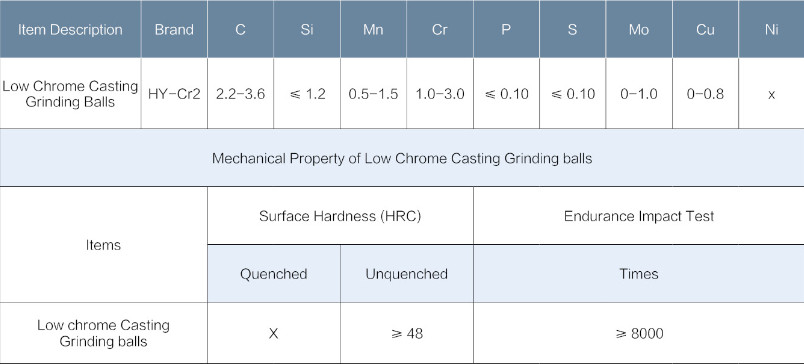

3. Low Chrome Grinding Balls

Inspection & Quality Guarantee ( Grinding Media Balls )

Preshipment SGS inspection at the factory or the harbor prior the dispatch.( no scrap or other steel quality used for manufacturing ). If the SGS test fails, the contract shall be canceled and the supplier shall transport back the grinding balls from the harbor at it’s own cost . The supplier has to achieve the steel bar tags and send the steel certificate bars showing the heat number and amount in tons per heat. The heat number shall be painted on the steel drums .

Packages ( Grinding Media Balls )

The grinding balls to be packed in steel drums with openable top or bulk bags.The plastic bags should be of good quality with 5:1 safety ratio .Drums or bags packed on pallets made of heat treated wood or plywood.

Jinan Haoyang Casting & Forging Co.,ltd as the direct manufacturer of grinding ,has been in the industry for about 30 years . We promisepat :

Our factory will be your qualified supplier and partner of Grinding media balls .

Compeitive price & factory direct prices

On time dispatch.

Preshipment inspection

Comprehensive logictics,

ISO certified factories

Haoyang have agent all over the world and provide grinding solutions for gold mining. All the goods will be inspected before loading on board. If test reports are unqualified , all the containers will be returned back at factory's cost ! We accept any claims caused by any problems of the steel.