The differences between Forging balls and Hot rolling grinding balls

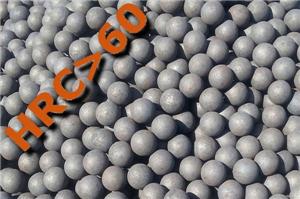

≥Dia 90mm grinding balls , we suggest customer choose the forging balls . As the big size balls , Via forging technique by air hammer (above picture ) . Heating of the steel rods then forging repeatedly by the air hammer . Because suffer the external force many times ,so the interior density will increase and grain refinement , so the toughness of balls will be improved . Better toughness and big size grinding balls will be not easily broken. Via our special heating treatment . the core and surface hardness will be improved .

By forging technique , our customer will get the better hardness and toughness grinding balls . Which will save mining money with better wearing rates and nearly “0” broken rate .

So the big size balls especially in the SAG , must guarantee the balls toughness and impact value , avoid the broken balls .

They choose Hot rollings to produce 50mm balls . customer told us Nearly local factories in Europe could produce small grinding balls by Hot rolling machine . but no Air hammer Forging machine . So Only China has the air hammer forging machine . which is our advantage to produce the big size balls .

Hot rolling machine

Larger production capacity than Forging balls

Suitable for 25mm-70mm Small size balls .

Round Steel via Hot rolling machine , directly to Round grinding balls , the small external force so the internal structure change little

Toughness and impact value will be lower than forging balls

If the raw materials( round steel ) have no enough compression ratio , the produced grinding balls will have worse toughness and impact value.

So the key to control hot rolling grinding balls quality is to choose the qualified raw material .

Small size balls are not easily broken out in the ball mill so we suggest choose the hot rolling technique balls .